Types of Thermal Insulation

Thermal insulation is the method of deduction of heat transfer between objects in thermal contact or the spectrum of irradiation impact. Thermal insulation consist of low thermal conductivity materials integrated to accomplish an even lower system thermal conductivity. Thermal insulation can be achieved with specially contrived techniques or strategies, as well as with adequate object contours and substances.

Thermal insulation are materials or a hybrid of substances fibrous, particulate, film or sheet, block or monolithic, open-cell or closed-cell that can be chemically or mechanically bound or aided to retard the velocity of heat flow by conduction, convection, and/or radiation. Insulation materials can be made in different configurations comprising loose-fill form, bat or blanket form, rigid form, foamed in place, or reflective form. The option of the adequate insulation substances structure and type depends on the variety of applications as well as the desired materials physical, thermal, and other properties. Most thermal insulation materials display heat flows by a medley of the three ways of conduction, radiation, and convection. This results in deviations of the insulating material thermal properties with density, or surface remittance, the hypothesis of a pure conduction mode is not valid, therefore, the term evident is implied in the term thermal conductivity of insulating materials.

Despite the enormous spectrum of applications accessible to fictionalized insulating materials, they all deliver comparable fundamental benefits: Lower energy expenses lead to incredible efficiency which results in greater returns on investment (Rois). Whether insulating residential compartment walls or shielding prudent machinists from high temperatures, all various kinds of insulation abide by these similar simple principles.

Before agreeing on which insulation material you think is good for you, there are numerous things you need to evaluate. What are the R-value, rate, sound insulation properties, and environmental consequences?

Types of thermal insulation

Mineral Wool

Mineral wool encompasses quite a few varieties of insulation. It could pertain to either insulator which is fiberglass produced from recycled glass or mineral wool which may be quiet insulation prepared from basalt. Mineral wool can be acquired in bats or as an open material. Largely mineral wool does not have additives to make it fire immune, making it bad for use in circumstances where drastic heat is present.

Fiberglass

Fiberglass is an exceptionally popular insulation substance. One of its key benefits is integrity. Because of how it’s created, by effectively intertwining fine threads of glass into an insulation material, fiberglass can minimize heat transfer. It is important when inducting fiberglass that the essential protection equipment is worn, as glass powder and tiny chips of glass are cropped up, which could potentially inflict injury to the eyes, lungs, and skin.

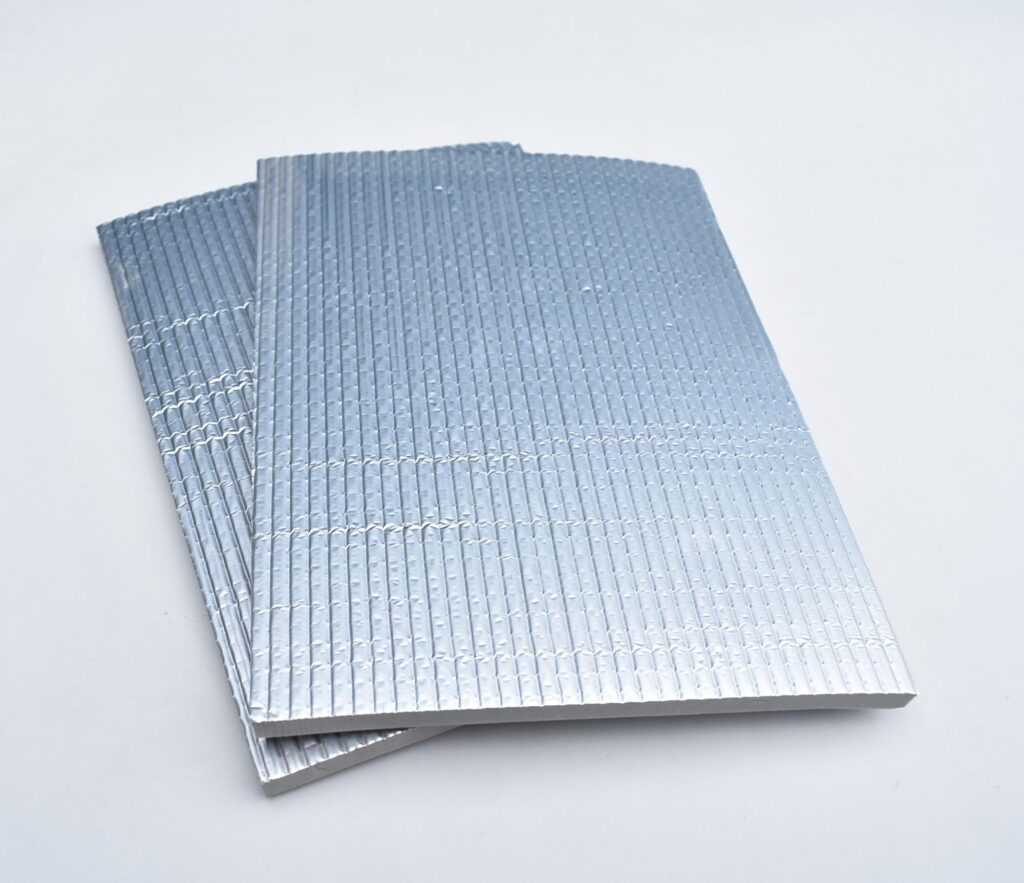

Polystyrene Form

Polystyrene may be a watertight thermoplastic foam that’s an impressive sound and temperature insulation material. It comes in two types, broadened (EPS) and extruded (XEPS) also known as Styrofoam. Polystyrene insulation has a uniquely polished surface that no other type of insulation possesses. It is used in both residential and retail settings. Polystyrene insulation is relatively rigid, unlike its fluffier substitutes. Generally, the foam is built or chopped into blocks, the standard for wall insulation.

Cellulose

Cellulose is an incredibly Eco-friendly form of insulation. It is 75-85% reclaimed paper fiber, usually post-consumer junk newsprint. Without oxygen within the substance, this enables to minimize the proportion of destruction that a fire can affect. So not only is cellulose possibly one among the foremost Eco-friendly configurations of insulation, but it’s also one among the foremost fire-resistant sorts of insulation.

Polyurethane Foam

This is other types of thermal insulation. Spray polyurethane foam (SPF) is prepared by blending and reacting chemicals to generate foam. The mixing and reacting substances react very rapidly, enlarging on touch to produce foam that insulates, air seals, and delivers a moisture boundary.